Product Detail

VSL Series

Quick Overview

SHUT OFF VALVE WITH RESTRICTED EXHAUST

Max Pressure: 150 to 250 PSIG (10 to 17 bar)Port Size: 1/2 to 1 in NPTF, G Tap Threads

Lockout valves prevent unauthorized pressurization of an air system during service or maintenance. Numatics lockout valves employ a unique, one piece center spool design that accommodates a user-supplied padlock in the closed position. When locked in the closed position, the system controlled by the lockout valve cannot be operated until the padlock is removed. Numatics lockout valves are available in several different designs, including standard manual full flow quick exhaust (VL Series - yellow body), Slo-Start™ full flow quick exhaust (VT Series - yellow body) and the Shut-Off Valve (VSL Series - grey body). The Shut-Off Valve (VSL Series - grey body) has a restricted exhaust and is typically used at the beginning of the FRL assembly. The addition of the Slo-Start™ feature to the lockouts allows for the downstream pressure to gradually increase prior to opening to a full flow condition.

Recommended Use

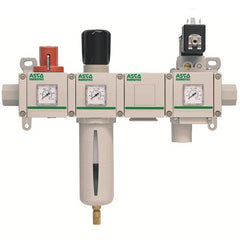

Install the Shut Off Valve upstream of an FRL assembly or selected air preparation components. Restricted exhaust capacity prevents potential damage to FRL or air preparation components due to excessive pressure drop in the reverse flow direction. Provides a method to exhaust FRL or air preparation assembly, when components require service.

Features

- Shut off valve – restricted flow exhaust of downstream pressure

- Meets OSHA specifications

- Grey body with red knob

- Integrated hole in valve spool for scissor “trades” lock

- Robust heavy duty construction

VSL32 Series

- Detented spool

- Low-friction startup

- Meets OSHA specifications

- Surface mountable

- Modular adaptable to 32 series FRL assemblies

- Grey body with red knob

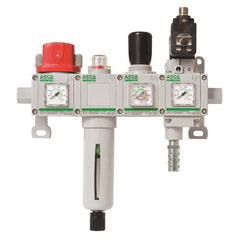

VSL42 Series

• Detented spool

• Low-friction startup

• Surface mountable

• Modular adaptable to 42 series FRL assemblies

• Grey body with red knob